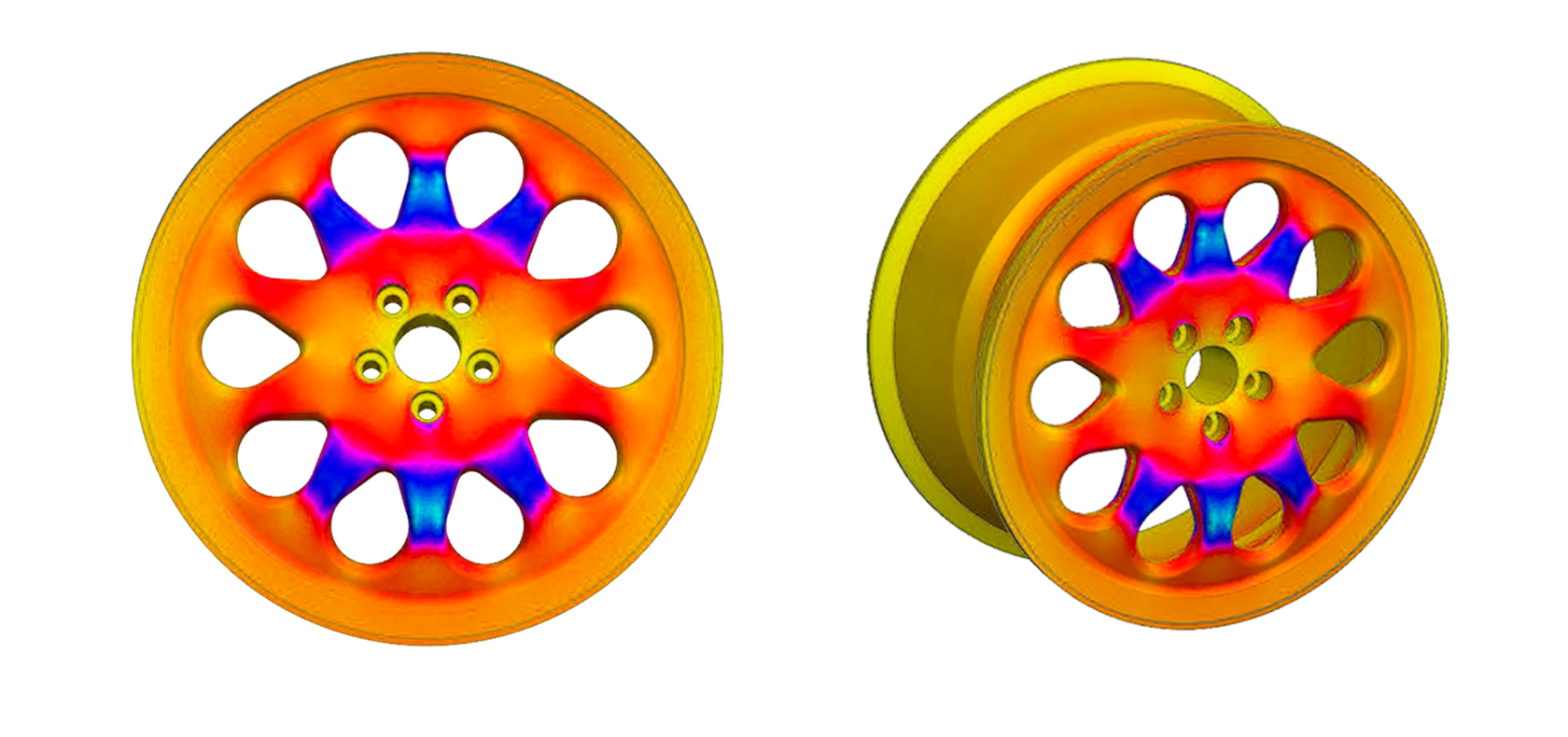

Although design projects can present various challenges, they can lead to rewarding outcomes when successful. In this case, our primary objective was to optimize the wheel design for use with polyamide while ensuring it can withstand all loads according to the necessary requirements. The process began with our engineering team creating a mathematical model to visualize the product and its properties, followed by conducting standard simulations to verify that the product met the required strength and durability.

The wheel disc made of glass fiber reinforced polyamide also has excellent impact resistance properties due to the added rim on the edges of the disk as well as reinforcing bushings for bolt holes to avoid cracks when tightening wheel fasteners. This design ensures that the wheel can withstand impact and maintain its shape and function. Additionally, the thermal insulation gasket prevents thermal conductivity through the contact spot and wheel bolts. This design ensures that the material retains its strength even under high temperatures, preventing strength loss due to the high temperature of operation.

This design boasts a significant advantage in that the mass of the disk is three times lower than that of aluminum alloy alternatives. The reduced weight of the wheel disc leads to decreased fuel consumption, ultimately resulting in higher efficiency.

Our company provides creative and innovative design solutions to tackle out-of-the-box tasks, bringing your ideas to life and achieving success in your project. If you have a project that requires innovative thinking and design solutions, we are here to help.